High current plug-in connector

High current connectors for fast, safe, and easy connections

Overview

We offer an extensive lineup of standard connectors and connectors with a mechanism to prevent wrong insertion.

FEPS also designs and manufactures custom-made products according to customer requests.

We also handle attachment processing with cables.

Features

- Compact connector structure

The structure enables space-saving design. - Easily attachable/detachable

The connector is design for easy attachment and removal. - Uses a band contact made of beryllium copper alloy

A high current removable design is available. - Uses silver plating

Achieves stable and long-term connection reliability. - Long-term stability

The plug-in structure achieves long-term connection stability thereby reducing maintenance and management man-hours. - Connectable using a commercially-available tool (JIS crimping tool)

No need for special tools for connecting to a cable.

FEPS designs and manufactures custom-made products according to customer requests.

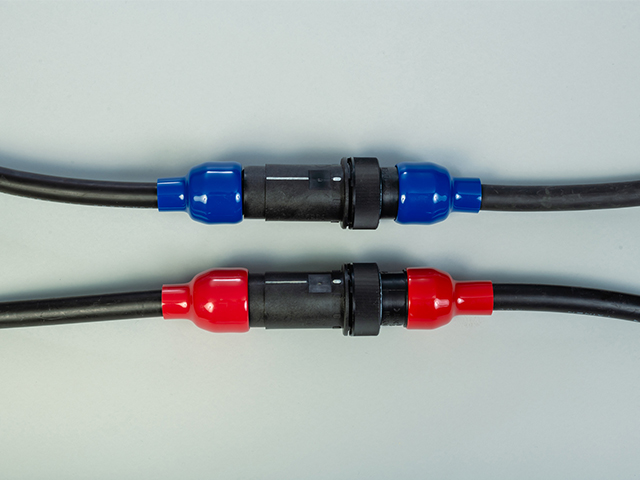

Connectors with mechanisms to prevent wrong insertion also feature the following functions.

- Screw-type lock structure

Easy to confirm successful connection by checking the tightening indication line and the feeling of fit created by the lock structure. - Equipped with a mechanism to prevent wrong insertion to other polarities (4 kinds)

[Patent: jointly patented with NTT FACILITIES, INC.]

Features a mechanism that uses concave-convex shaped key holes to prevent wrong insertion. This prevents electric shock and short circuit accidents due to mistaken installation. We can also attach an optional identification cover and identification ring to enable visual confirmation of the connection system.

- (Note) Connectors cannot be attached or removed when power is flowing. (Doing so is dangerous and must never be attempted.)

Use

- Semiconductor manufacturing equipment

- Heaters, electric furnaces, exposure equipment

- EVs, railways, AGVs

- UPS, inverters

- New power supply equipment, switchboards

Specifications

Scroll right to view more information

| Contact material | Silver plated beryllium copper alloy |

|---|---|

| Metal conductor material | Silver plated electrolytic copper |

| Insulation cover material (with a mechanism to prevent wrong insertion) | PBT (UL 94 V-0) * Identification cover: Polyvinyl chloride. |

| Insulation cover material (standard type) | Glass fiber reinforced 66 nylon (UL 94 V-0) * Product for 20 mm diameter is polyacetal (UL 94 HB) |

| Wire connection method | Same as JIS C 2805 “Crimp-terminal lugs for copper conductor” |

| Rated current | 355 A (100 mm²), 545 A (200 mm²), 700 A (325 mm²) |

| Rated voltage | 600 V/DC-AC |

| Maximum operating temperature | 100°C (includes temperature due to electric conduction) |

| Connecting cable kind | CF・CV・EM-LMFC, etc. |

Scroll right to view more information

| Cable size | Applicable wire range (mm2) |

|---|---|

| 22 | 16.78 - 22.66 |

| 38 | 26.66 - 42.42 |

| 60 | 42.42 - 60.57 |

| 70 | 60.57 - 76.28 |

| 100 | 96.3 - 117.2 |

| 150 | 117.2 - 152.05 |

| 200 | 192.6 - 242.27 |

| 325 | 242.27 - 325 |