Electrical tape

Strength in application on terminal and connection for electric wires and cables

We offer a lineup of six types of tapes made possible by our experience in electrical insulation technology and synthetic resin application processing technology.

Please use the appropriate tape to fit your usage needs.

High-voltage insulating tape: F-CO Tape No.2

F-CO Tape No.2 is a high-voltage insulating tape composed of a polyethylene base with butyl rubber as the main component. The tape is laminated with a self-bonding adhesive material.

We offer tape for insulation of connecting parts and terminal parts of various rubber and plastic cables, as well as tape for repair of damaged insulators on cables.

JCAA D 004 compliant

- (Note) JCAA: Japan Power Cable Accessories Association

Features

This product complies with specifications for Black-Colored Adhesive Polyethylene Insulating Tape of the Interior Wiring Standards (in Japanese).

It is widely used for insulating the joints and terminals of various rubber- and plastic-insulated cables up to 69 kV.

Use

Electrical insulation tape for 100 V to 69 kV

- To insulate the terminals and joints of high voltage cables and electric wires

- To repair cracks in insulation of cables and electric wires for high voltage

- To protect insulation cover and clamp cover attachments from water, provide insulation, and prevent misalignment

Structure/material

How to use

- While gently stretching the tape so that it adheres to the object without wrinkling (stretch to the extent that the original tape width is reduced by 1 to 2 mm), wind the tape half-lapped with the adhesive side inside. Do not stretch the tape too much because excessive tension tends to cause misalignment.

- In cold weather, warm the tape slightly by putting it in your pocket, etc. (use the tape at a temperature of +5°C to +30°C).

Properties

Scroll right to view more information

| Item | Property | |

|---|---|---|

| Tensile strength (N/mm²) | Normal temperature | 4 |

| Elongation (%) | Normal temperature | 450 |

| Volume resistivity (Ω-cm, 20°C) | 1 x 1016 | |

| Insulation breakdown strength (kV/mm) | 30 | |

| Adhesive strength (N/20 mm) | 30 | |

| Ozone resistance | Excellent | |

| Tracking resistance | Excellent | |

| Water resistance | Excellent | |

- (Note) These are measured values and are not guaranteed.

Size / packing unit

Scroll right to view more information

| Thickness (mm) | Width (mm) | Length (m) | Packing units (rolls) |

|---|---|---|---|

| 0.5 | 20 | 10 | 100 |

| 40 | 50 |

Tape for filling: F-CO Tape No. 1

F-CO Tape No. 1 is a self-bonding tape composed mainly of a butyl rubber-based adhesive material, which is formed into the shape of tape.

Use this tape to fill up cable joints and branches where it would be difficult to wind F-CO Tape No. 2.

Use this tape in combination with F-CO Tape No. 2.

Features

- Perfect self-bonding

Adheres perfectly to the adhesion layer of F-CO Tape No. 2. - Ideal hardness for filling

Use your fingers to easily shape the tape and fill small areas with little force.

Use

- Use for filling areas where it is difficult to wrap F-CO Tape No. 2 due to large unevenness between cable connections and branches.

- (Note) This tape is an insulating material for filling. Be sure to wrap F-CO Tape No. 2 on top of this tape.

- (Note) Please use F-CO Tape No. 2 to ensure the necessary insulation performance.

How to use

- After adequately cleaning the object surface, wind the tape half-lapped while peeling off the separator and stretching the tape to the extent that its original width is reduced by 4 to 5 mm. This stretching will prevent air from being trapped under the tape.

- When using to fill spaces, form the tape into an appropriate shape in advance while being careful not to include air. For use in cold seasons, warm the tape to around room temperature before using.

Properties

Scroll right to view more information

| Item | Property | |

|---|---|---|

| Tensile strength (N/mm²) | Normal temperature | 0.5 |

| After heat aging | 0.7 | |

| Elongation (%) | Normal temperature | 1,000 or higher |

| After heat aging | 1,000 or higher | |

| Volume resistivity (Ω-cm, 20°C) | 1 x 1016 | |

| Insulation breakdown strength (kV/mm) | 30 | |

| Self-bonding | Excellent | |

| Hardness (degree of penetration) | 31 | |

- (Note) These are measured values and are not guaranteed.

Size / packing unit

Scroll right to view more information

| Thickness (mm) | Width (mm) | Length (m) | Packing units (rolls) |

|---|---|---|---|

| 1.0 | 20 | 5 | 100 |

Halogen-free flame-retardant tape: NON-HALO F-CO ENB

NON-HALO F-CO ENB is a halogen-free adhesive tape that is flame retardant and does not emit toxic gases such as halogen gases when incinerated.

This environmentally friendly tape is a suitable alternative to PVC tape. Please use this tape for insulation, protection, and bundling of power cables and communication cables up to 600 V.

JCAA D 005 compliant

- (Note) JCAA: Japan Power Cable Accessories Association

Features

- Easily cut by hand like PVC tape

This tape is easily cut by hand and it wraps as smoothly as PVC tape. - No emission of halogen gas

The tape does not use any materials containing halides.

Use

- For insulation, protection, and bundling of power cables and communication cables of 600 V or less

How to use

- Adequately clean the surface of the object. While gently stretching the tape so that it adheres to the object without wrinkling, wind the tape half-lapped with the adhesive side inside. Do not stretch the tape too much because excessive tension tends to cause misalignment and tearing.

- In cold weather, warm the tape slightly by putting it in your pocket, etc. (use the tape at a temperature of +5°C to +30°C).

Properties

Scroll right to view more information

| Item | Property | JCAA D 034 specifications |

|---|---|---|

| Tensile strength (N/19 mm) | 35 | 28.5 or higher |

| Elongation (%) | 300 | 100 or higher |

| Shear adhesive strength (N/19 mm) | 39 | 28.5 or higher |

| Dielectric breakdown strength (kV/0.2 mm) | 12 | 6 or higher |

| Flame retardance | Excellent | 600Kw / m2x 10 sec or lower |

| Volume resistivity (Ω/cm) | 6 x 1014 | 1 x 1012or higher |

- (Note) These are measured values and are not guaranteed.

Size / packing unit

Scroll right to view more information

| Thickness (mm) | Width (mm) | Length (m) | Packing units (rolls) |

|---|---|---|---|

| 0.2 | 19 | 10 | 100 |

Self-bonding electric insulation tape for high-voltage insulation: F-CO Tape No. 35

F-CO Tape No. 35 is a self-bonding electric insulation tape for high-voltage insulation. It is mainly composed of EPDM.

JCAA D 005 compliant

- (Note) JCAA: Japan Power Cable Accessories Association

Features

- Superior self-bonding

After the tape is wound, it bonds uniformly to form an insulating layer that does not trap air. - Unvulcanized EPDM composition

By using special EPDM, this tape maintains a stable stress cone shape even though it is non-vulcanized.

Use

- For insulation of 6.6 kV–69 kV power cable joints.

How To use

- After adequately cleaning the object surface, wind the tape half-lapped while peeling off the separator and stretching the tape evenly to the extent that its original width is reduced by 40% to 50%.

Properties

Scroll right to view more information

| Item | Property | Test method | |

|---|---|---|---|

| Tensile strength (N/mm2) | Normal temperature | 4 | After heating at 100°C for 96 hours JIS K 6251 |

| After heat aging | 3.9 | ||

| Elongation (%) | Normal temperature | 900 | After heating at 100°C for 96 hours JIS K 6251 |

| After heat aging | 900 | ||

| Volume resistivity (Ω-cm, 20°C) | 1 x 1016 | JIS C 2107 | |

| Dielectric breakdown strength (kV/mm) | 50 | JIS C 2110 | |

| Dielectric power factor (%) | 0.4 | JIS K 6911 | |

| Dielectric Constant (ε) | 2.9 | JIS K 6911 | |

| Self-bonding | Excellent | After 1 hour | |

| Ozone resistance | Excellent | 1 hour at 0.015 vol %, 25°C, 20% elongation | |

- (Note) These are measured values and are not guaranteed.

Size / packing unit

Scroll right to view more information

| Thickness (mm) | Width (mm) | Length (m) | Packing units (rolls) |

|---|---|---|---|

| 0.5 | 20/30 | 10 | 100/50 |

Adhesive rubber tape for insulating and waterproofing: F-CO Tape No. 70

F-CO Tape No. 70 is an insulating and waterproofing tape. It is composed of a vulcanized EP rubber sheet laminated with a special rubber-base to create a non-separator.

Features

- Non-separator

This tape is a non-separator even though it is a rubber-based adhesive tape. It is an environmentally friendly tape that does not contain environmentally hazardous substances. - Superior waterproofing

This tape is flexible, has a strong tightening force, and achieves high watertightness.

Use

- For insulation, protection and waterproofing of the joints and branches of mid- to low-voltage overhead distribution cables.

- Fixation of insulating covers and enhanced waterproofing of terminals

Structure/material

How to use

- Wind and apply the tape while stretching it to the extent that it elongates by 50%. Use scissors or a knife to cut the tape end.

Do not stretch the tape end. Press it down firmly.

Properties

Scroll right to view more information

| Item | Properties | Test method | |

|---|---|---|---|

Tensile strength N/mm2 |

3 | JCAA B 003 | |

| Elongation % | 500 | ||

| Overlay adhesive strength (N/20-mm width) (Lap Shear) | 55 | ||

| Volume resistivity Ω-cm (20°C) | 2 x 1015 | ||

| Breakdown voltage (kV/mm) | 30 | ||

| Water resistance | Excellent | ||

- (Note) These are measured values and are not guaranteed.

Size / packing unit

Scroll right to view more information

| Thickness (mm) | Width (mm) | Length (m) | Packing units (rolls) |

|---|---|---|---|

| 1.0 | 50 | 3 | 40 |

- (Note) Please consult with us regarding inquires on width and length.

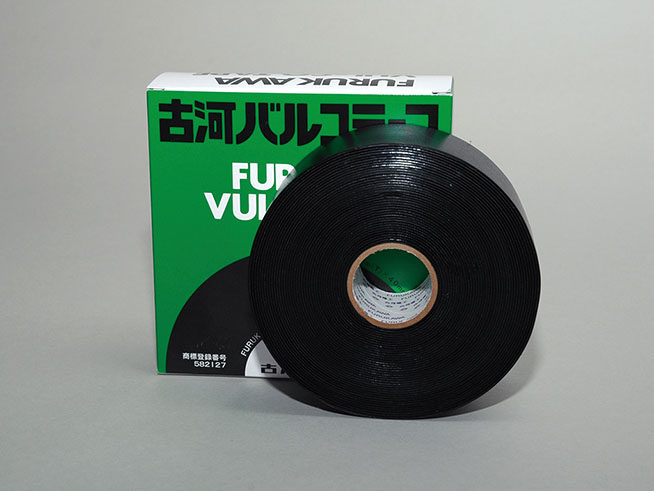

Protection and waterproof tape: VUL-CO TAPE

VUL-CO Tape is based on a vulcanized rubber sheet with superior mechanical strength. The sheet is coated with a self-bonding adhesive that provides outstanding waterproofing. The result is a tape for protection and waterproofing.

VUL-CO Tape achieves superior mechanical strength by coating a vulcanized chloroprene rubber sheet with a self-bonding adhesive material.

JCAA D 006 compliant

- (Note) JCAA: Japan Power Cable Accessories Association

Features

- Superior waterproofing and protection

In dusty locations, it protects the insulating tape from dust. In locations prone to contact from tree branches, it protects the underlying layer from damage. Possesses superior protection and waterproof performance that prevents moisture from entering, thereby preventing dielectric breakdown.

Use

- To protect and waterproof insulation tape on the connection of electric cables and wires

- To protect, waterproof, and repair cracks of sheath material of electric cables and wires

- To protect insulation tape lapped on the insulation cover of wires and clamp covers

- (Note) This tape is for protection and waterproofing. It cannot be used for insulation.

Structure/material

How to use

- Peel off the separator before use.

- Adequately clean the surface of the object. Wind the tape half-lapped with the adhesive side inside while gently stretching the tape (about 20%) so that it adheres to the object without wrinkling.

- Do not stretch the tape too much because excessive tension tends to cause misalignment.

- Do not stretch the tape end. Press it down firmly.

Properties

Scroll right to view more information

| Item | Property |

|---|---|

| Tensile strength (N/mm²) | 8 |

| Elongation (%) | 500 |

| Adhesive strength (lapping) (N/20-mm width) (Lap Shear) | 100 |

| Oil resistance | Excellent |

| Water resistance | Excellent |

| Weather resistance | Excellent |

| Ozone resistance | Excellent |

- (Note) These are measured values and are not guaranteed.

Size / packing unit

Scroll right to view more information

| Thickness (mm) | Width (mm) | Length (m) | Packing units (rolls) |

|---|---|---|---|

| 1.0 | 20 | 10 | 60 |

| 40 | 30 |